Choosing the Right Corrugated Box for your Product is crucial for business across various industries because it directly impacts product safety, customer satisfaction, and operational efficiency.

This blog will help you in providing key information as to why choosing the right corrugated box is important for the product.

Contents

- 1 Introduction

- 2 Objective of Blog:

- 2.1 Why choosing the right corrugated box is crucial for business across?

- 2.2 Steps in Choosing the Right Corrugated Box

- 2.2.1 Following are the main steps that will guide you to choose the right corrugated boxes:

- 2.2.1.1 Identification of Your Product Requirements

- 2.2.1.2 Evaluate Box style, design and customization:

- 2.2.1.3 Printing and Branding Needs:

- 2.2.1.4 Assess Environmental and Sustainability Impact

- 2.2.1.5 Compliance with Industry Standards:

- 2.2.1.6 7. Cost analysis and Supplier selection:

- 2.2.1.7 Testing and Validation of the Box

- 2.2.1.8 Consider Shipping and storage environment:

- 2.2.2 Conclusion:

- 2.2.1 Following are the main steps that will guide you to choose the right corrugated boxes:

Introduction

Corrugated boxes are among the best solutions available for the businesses looking for cost-effective and reliable packaging.

By providing safe, efficient, and durable packaging solutions for a wide variety of products, these corrugated boxes have become one of the major components of packaging industry.

Corrugated Box have become all the more valuable and important, with the advent and popularity of online business and e-commerce. Custom Corrugated Boxes are widely used to transport approximately 95% of the goods to retail stores and other customers as per their requirements.

The Corrugated Box is an essential tool for manufacturers when it comes to transporting their products. It is often regarded as the standard shipping container. These boxes are one of the most flexible and commonly used shipping solutions available due to their customizable design.

These custom boxes are perfect for heavier and more brittle items as lightweight cartons often cannot hold the products’ weight.

Corrugated Boxes are not just restricted to packaging, they are a significant tool that conveys brand values, boost customer loyalty, and strengthen market presence.

Objective of Blog:

This blog will help you understand the main factors to consider when choosing the right corrugated box as per your specific needs.

In this post, we will explore various benefits of corrugated boxes for different industries, go in-depth into the various aspects of corrugated material, look into quality control, and discuss the benefits and uses of such material.

In this blog post, we’ll also provide some tips on how to choose the right corrugated box for your products.

By the end of this article, we hope to give you a better understanding of corrugated boards, so that you can make the best decision for your product’s packaging

So, what is Corrugated Box? & why it should be used for product packaging?

Keep on reading the entire blog to know everything about corrugated boxes and how to choose the right corrugated box as per your business needs!

A corrugated box is a shipping box made from paper board that’s strong, durable and light weight.

It is a container made from sheets of packaging material also called, corrugated cardboard. Corrugated boxes are made from thick paper; providing cost-effective solutions. Made of paper pulp, they are having three layers of kraft paper, with a wavy inner layer called the corrugated medium that gives the box its durability and strength.

Why choosing the right corrugated box is crucial for business across?

The main reasons why companies’ repeatedly choose corrugated packaging are:

- Structural rigidity

- Protection & safety of products

- Provides cushioning for fragile products: These boxes provide superior cushioning for safe product delivery.

- Customer satisfaction and brand image: Using boxes as a source for branding is a cost-effective method to make a company’s identity stand out.

- Customization: They are easy to customize in terms of color, design, shape

- Easily recyclable, eco-friendly and sustainable: Corrugated boxes are environmentally friendly and 100% recyclable.

- Versatility: These boxes are easily adaptable to various product sizes and shapes.

- High Quality printing: Another main feature of corrugated boxes is having an option to print on them, including embodying a company’s logo.

- Efficient supply chain management

- Compliance with industry standards

- Lightweight & cost effective: If you’re looking for long-term, long-distance packaging, corrugated packaging is lightweight and budget friendly.

- Resistance to moisture, temperature changes and weather events various industries

Steps in Choosing the Right Corrugated Box

Before diving into this box world, it’s important to consider specific needs.

Some of the basic questions to ask yourself:

Product focus: What are you shipping or storing? Are they delicate items, heavy machines, or some fancy item? Different products have different needs depending upon the items shape, size, and weight.

Following are the main steps that will guide you to choose the right corrugated boxes:

Product Weight and Dimensions:

Identification of Your Product Requirements

The first step in choosing the right corrugated box is to completely understand your product’s features and requirements.

Size and Weight: Measure the dimensions and weight of your product. Knowing the exact weight and dimensions of your product is an important factor to be considered. Will you be shipping heavy machinery parts or delicate glass container? Choosing a box that fits your product eventually helps in preventing movement during transit, thereby lowering the risk of damage.

Product Fragility

Identification of the product for its fragility and whether it is perishable or requires some kind of special handling is crucial.

Fragile items require additional cushioning and support, which may influence the box design. Using extra cushioning materials like foam inserts or air pillows offers great deal of protection and care to the product.

By determining how delicate or strong your product is, you can choose the box that best fits your needs.

Shape: Custom box designing of the product is required for the one having an unusual shape. This needs to be identified in the very beginning stage of the box selection.

Consider Customization Options

Corrugated boxes can be customized in many ways, including size, shape, colour, and branding. Consider whether you need a custom-sized box or a box with your company’s logo printed on it.

Quantity:

Bulk packaging requires sturdier boxes and effective internal dividers. Decide the number of products to be shipped in a single box.

Determine the Box Strength and type:

Corrugated boxes are made from different variety of materials, each providing different levels of strength and durability. The most common materials include:

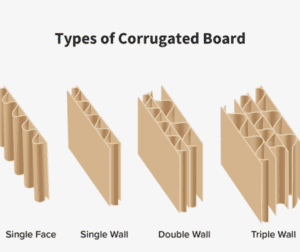

Single Wall: These types of boxes are made with one layer of corrugated cardboard. They are made of three layers; outer recycled cardboard liner, corrugated inner liner and another recycled layer. It is also called as 3 ply box. 3 ply boxes are ideal for packaging light weight products. They are cost effective and most preferred by ecommerce and online business.

Double Wall: These boxes are made of two layers of corrugated medium between three layers of linerboard. These types of corrugated boxes are the best way to store and transport heavy items. They are most commonly used for shipping electronics and valuable items. They provide exceptional level of durability, strength and versatility that is used by different industries all over.

Triple Wall: These type of corrugated boxes are made of three layers of corrugated medium between four layers of linerboard. Businesses use triple wall boxes to ship heavy and bulky items such as heavy duty, industrial equipment’s and packaging, pumps, boilers etc.

Evaluate Box style, design and customization:

Corrugated boxes are of different styles, each suited for different purposes. Some of the common styles are:

Regular Slotted Container (RSC): The one is the most common box style which is suitable for a wide range of products. Under this style, all flaps have the same length and are usually half the box’s width.

Full Overlap Container (FOL): this style provides extra strength and stacking ability which is perfect for heavy items. The outer flaps overlap the full width of the box, providing extra strength and durability.

Half-Slotted Container (HSC): Similar to RSC but with an open top, often used with a lid. ideal for applications where the box contents need to be easily accessible.

Die-Cut Custom Boxes: Custom-shaped boxes designed to fit unique product dimensions and shapes.

Consider the Flute Type

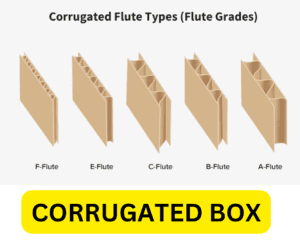

In corrugated boxes, the flute type refers to the wave-shaped structure between the linerboards. Different flute types provide different levels of cushioning and strength:

A-Flute: Offers excellent cushioning and compression strength. This is suitable for fragile items.

B-Flute: Provides good stacking strength and puncture resistance. Commonly used for retail packaging.

C-Flute: A versatile option that offers a balance of cushioning and stacking strength. Widely used for shipping boxes.

E-Flute: This one is most suitable for retail and display packaging. Being thin and lightweight, it provides a smooth surface for high-quality printing

F-Flute: Being extremely thin and flexible, this one is most suitable for small retail packaging and custom shapes.

Printing and Branding Needs:

Decide if the boxes need custom printing for branding, instructions or barcodes. Printed boxes can enhance brand recognition and provide information directly on the packaging.

Consider the printing options available for corrugated boxes, if branding and aesthetics are important for your packaging.

- Digital Printing: Allows for full-color, high-resolution graphics and is suitable for short runs and customized designs.

- Flexographic Printing: Economical and suitable for simple designs with limited colors.

- Lithographic Printing: Provides high-quality, detailed graphics and is ideal for retail packaging.

Assess Environmental and Sustainability Impact

Look for boxes made from recycled materials and explore eco-friendly options.

Look for Sustainable Packaging Options. As consumers become increasingly environmentally conscious, sustainable packaging options are becoming more popular. By looking for corrugated boxes made from recycled material and choosing a supplier who prioritizes sustainability, you can find an eco-friendly packaging solution for your products.

This is the main ecological benefit of corrugated boxes that they are made mostly of recycled paper. Most corrugated packaging is made without dyes and bleaches, meaning it can be disposed of more sustainably than other types of material that contain contaminants.

Many corrugated box styles are designed to be easily collapsible and fully reusable.

Compliance with Industry Standards:

Ensuring the boxes meet any industry specific packaging regulations such as those required for food, pharmaceuticals or hazardous materials. In modern packaging, sustainability and compliance with regulations are most crucial factors. Do ensure that the box packaging meets industry standards and regulations for safety, hygiene, and quality.

7. Cost analysis and Supplier selection:

Making sure that box is of perfect size, so that you’ll need less packing material to fill the extra space. By using a smaller box that perfectly fits your product, you can reduce your dimensional weight and qualify for lower shipping rates.

Also choose a reliable supplier, who can provide you consistent quality, customization options, and flexible order quantities.

Testing and Validation of the Box

In order to ensure that the box meets the necessary standards for protection, durability and performance, it is very important to test the box.

This factor is crucial to ensure product safety during shipping, handling and storage.

Proper validation process is essential to assess the quality of material, box construction and board grade.

Testing and validation also ensures that your packaging complies with industry standards and regulations. It helps in optimizing cost and build brand reputation.

It provides confidence that your packaging solution is absolutely fit for reliable, purpose and cost effective.

Consider Shipping and storage environment:

It is very important to consider the shipping and storage environment that your products will be exposed to. This ensures that your packaging is efficient, cost effective, sturdy and provide safety of products from beginning till end.

Selecting the right box size helps in reducing shipping cost, minimizes wastage and ensures stackability and stability of boxes.

Finding the perfect box supplier is simple! A quick web search for top 10 box packaging providers or custom box packaging or corrugated box will provide you with ample amount of options. You can also search for more information regarding different corrugated box design in Wikipedia.

Why choose Ashwani Packers as Your Corrugated Box Manufacturer

At Ashwani Packers, we specialize in providing high-quality corrugated boxes tailored to meet your specific needs.

We believe that choosing the right corrugated box for your business is a crucial decision. It’s about providing tailored solutions by understanding your business specific needs and thereby optimizing your supply chain.

Ashwani Packers deals in all types of designing, printing, and corrugated box packaging. Having an experience of more than 25 years in this industry, we provide extraordinary and remarkable printed and plain white and brown box packaging solutions.

Here’s why you should choose Ashwani Packers:

Sustainability: To minimize environmental impact, we are committed to sustainability and using eco-friendly materials and processes.

Expertise and Experience: Having an experience of more than 25 years in this industry, we offer expert guidance and expertise in selecting the accurate box for your product.

Customization: By ensuring your packaging stands out and meets all your requirements, we offer a variety of customization options, from box styles and sizes to printing and branding.

Quality Assurance: To ensure durability and reliability, our boxes are manufactured using high quality materials and go through diligent quality control. Using high-quality material and following advanced manufacturing processes is our top most priority.

Competitive Pricing: We offer competitive pricing, and ensure to provide the best value for your investment without compromising on quality.

Timely Delivery: At Ashwani Packers, we believe in timely production and delivery to avoid any delays and meet your business needs. With a commitment to superior customer service, on-time order completion, and high quality packaging, we promise to support you through every step of our manufacturing process.

Customer centric approach: We believe in ensuring satisfaction at every stage of the entire box making process by providing personalized customer service and paying due attention to your needs.

Locally Trusted: Our high quality box packaging and state of the art equipment has made us a preferred choice in the local market.

Free Design Service: Our professional graphic designer’s team will provide you with appealing designs to enhance your ideas and boxes.

High Quality Printing Options: The Company’s cutting-edge digital and offset printing services allow you to include creative designs in your customized printed boxes.

Innovative Solutions: We provide innovative solutions for your packaging needs as per the latest trends and industry standards.

Contact Ashwani Packers today and do visit our website: https://samayprintpack.com , if you want to partner with an experienced, reliable and customized box provider to discuss your corrugated box requirements and to achieve the right packaging solutions as per your need.

For further information on Ashwani Packers as a customized box packaging provider and other corrugated box manufacturers in Delhi as well, please don’t forget to go through our other blog “Top 10 Box providers in Delhi”.

Company unit and office is located in Bawana Industrial Area, Phase 1, New Delhi, conveniently connected to all of the NCR towns, New Delhi, Faridabad, Gurgaon and Noida.

Website: www.samayprintpack.com; Contact number: +91 9212739905, +91 9873275115

Email: kochhar.mehak@gmail.com

Conclusion:

Choosing the right corrugated box for your business plays a critical role in ensuring that your product reaches safely during shipping and transit and also saving your money in the entire process. It’s an opportunity to showcase your brand, keep your customers satisfied and to attract new clients.

By partnering with right and reliable packaging provider, like Ashwani Packers, you can further enhance your packaging strategy and ensure that your product reaches in safe hands.

Finally hoping this blog assists you in providing all the required information and tips for choosing the right corrugated box provider for your business. By making wise and informed choices, you’ll surely outgrow both your business operations as well as customer satisfaction.

Contact Ashwani Packers today, to discuss all your corrugated box needs and create the perfect corrugated box solution for your products.